PCB Prototyping

Why choose M.E.A.Tec?

At M.E.A. Tec Inc., we understand that the journey from concept to market-ready product begins with effective prototyping. Our PCB Prototyping Services are designed to transform your innovative ideas into functional prototypes swiftly and efficiently, setting the foundation for successful product development.

Our PCB Prototyping Process

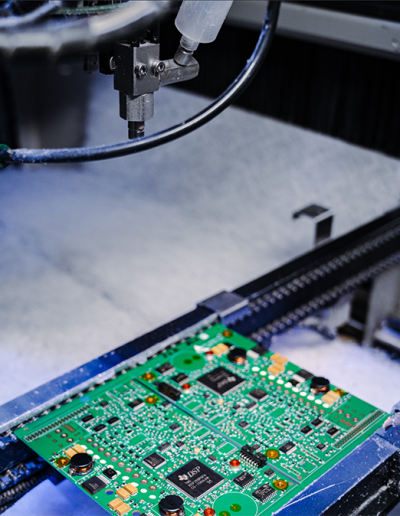

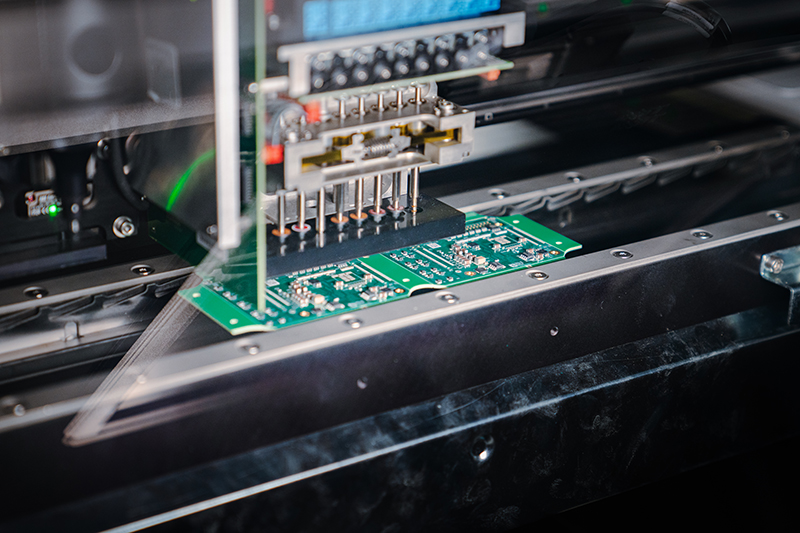

Dedicated SMT Prototyping Lines: We have invested in a specialized Surface Mount Technology (SMT) prototyping lines, ensuring that your prototypes receive focused attention and precision. This dedicated lines allows us to handle complex designs with ease, maintaining high-quality standards throughout the process.

Rapid Turnaround: Time-to-market is crucial in today’s competitive landscape. Once we receive all components, our prototyping line delivers fully assembled prototypes within 2 to 3 days. This swift turnaround enables you to expedite testing phases and accelerate your product development cycle.

Cost-Effective Solutions: Our efficient prototyping process reduces costs, allowing you to explore multiple design iterations without financial constraints. This flexibility empowers you to experiment with innovative solutions, enhancing the overall quality and functionality of your final product.

Latest Techniques

Innovative Technology

Certified Experts

The M.E.A. Tec Prototyping Journey

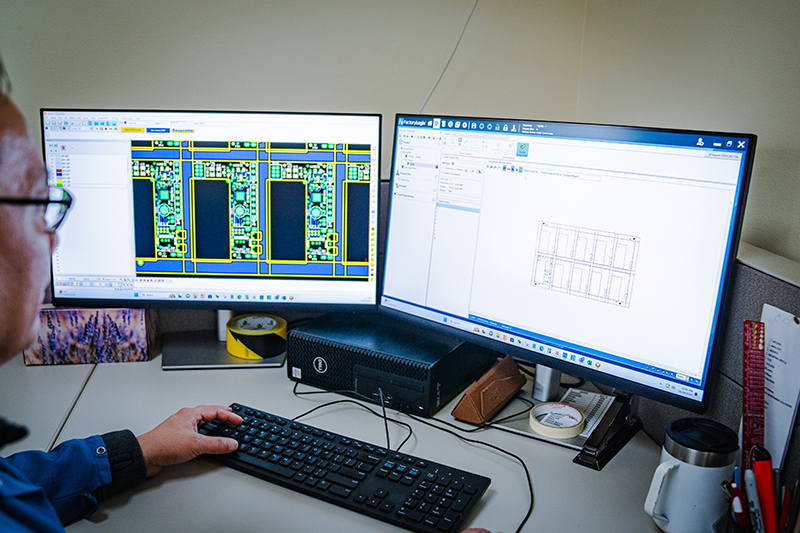

Consultation and Design Review: We begin by understanding your project requirements and reviewing your design files to ensure they are optimized for manufacturing. Our experienced engineers provide feedback to enhance design efficiency and performance.

Component Procurement: Leveraging our extensive network of trusted suppliers, we source high-quality components promptly, ensuring that all parts meet your specifications and are ready for assembly.

Assembly: Utilizing our dedicated SMT prototyping lines, we assemble your PCB with meticulous attention to detail. Our advanced equipment and skilled technicians ensure precise placement and soldering of components.

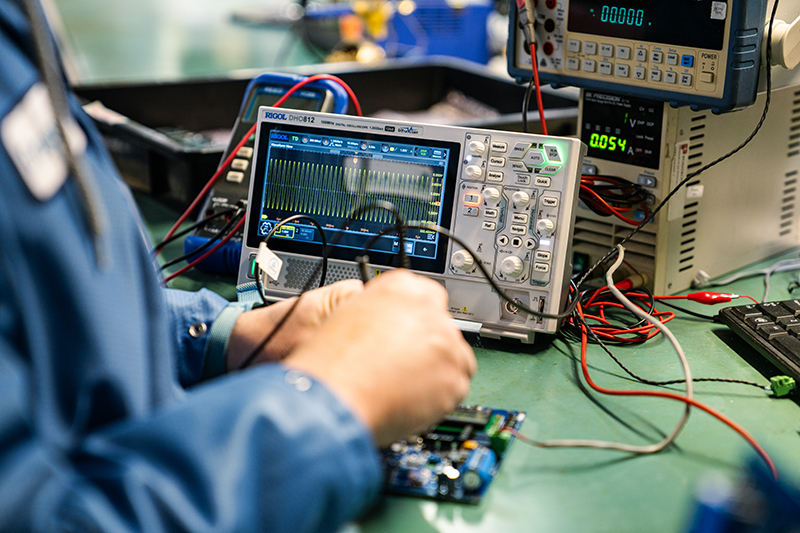

Testing and Quality Assurance: Each prototype undergoes rigorous testing to verify functionality and adherence to design specifications. Our quality assurance processes identify and address any issues, ensuring that your prototype performs as intended.

Feedback and Iteration: We collaborate with you to assess the prototype’s performance, incorporating your feedback to refine and improve the design. This iterative process ensures that the final product aligns perfectly with your vision and requirements.

Benefits of Partnering with M.E.A. Tec

Expertise and Experience: With over 30 years in the industry, our team possesses the knowledge and skills to handle diverse and complex prototyping projects, ensuring your ideas are realized effectively.

Flexibility: Our prototyping services accommodate various project scopes, from small-scale prototypes to more extensive pre-production runs, providing solutions tailored to your specific needs.

Enhanced Innovation: By offering low-cost and fast-turnaround prototyping, we enable you to explore creative design choices that may have previously been unattainable, fostering innovation and competitive advantage.

Family Owned

Let M.E.A.Tec Prototype

At M.E.A. Tec, we combine speed, quality, and affordability in our prototyping services. Our dedicated SMT lines ensures rapid assembly without compromising on precision, while our streamlined processes reduce costs, allowing you to focus on innovation. This unique blend of efficiency and excellence positions us as a preferred partner for your PCB prototyping needs.

Ready to transform your concept into a tangible prototype? Partner with M.E.A. Tec for fast, reliable, and cost-effective PCB prototyping services. Contact us today to discuss your project requirements and discover how we can assist in bringing your ideas to life